|

|---|

Factory in terms of Architecture of Care

in case of turkey

by

Kian ShamshirI

FACTORY

ARCH 501

Research Framed Questions and hypothesis

-

Air Pollution and Health Effects:

-

What specific pollutants are emitted by the factory, and what are their potential health effects on the local population?

-

Are there any noticeable trends in air quality data, such as increased levels of particulate matter or volatile organic compounds, since the factory's operation?

-

-

Soil and Environmental Impact:

-

What historical landmarks, natural features, or cultural sites in the vicinity have been impacted by the factory's presence and activities?

-

How have these changes affected the local community's sense of identity and cultural heritage?

-

-

Soil Contamination and Remediation:

-

Has the factory been responsible for soil contamination in the area? If so, what types of contaminants are involved, and what are their concentrations?

-

Are there any ongoing or proposed remediation efforts to address soil contamination and protect the local environment?

-

-

Working Conditions and Labor Practices:

-

What are the labor conditions and practices within the factory, including wages, working hours, and safety measures?

-

Have there been any labor-related disputes or concerns raised by workers or labor organizations?

-

Methodology and Terms

Term 1: Preliminary Assessment

-

Site Selection: Identify and select the specific factory location as the case study site, ensuring it is representative of the problem at hand.

-

Stakeholder Engagement: Establish communication with the factory management, local community representatives, and relevant government agencies to gather information and gain cooperation.

-

Problem Framing: Clearly define the scope of the study, specifying the factory's operations, pollutants involved, and the geographic extent of environmental impact.

-

Regulatory Framework Review: Familiarizing with relevant environmental regulations, standards, and guidelines that apply to the factory's operations.

Term 2: Data Collection and Analysis

-

Air Pollution Assessment:

-

Deploy air quality monitoring equipment to measure pollutants emitted by the factory.

-

Collect meteorological data to understand the dispersion of pollutants.

-

Analyze air quality data and assess compliance with air global quality standardization.

-

Estimate health and environmental risks associated with air pollution.

-

-

Ground and Soil Contamination Assessment:

-

Conduct soil sampling at various locations within and around the factory.

-

Analyze soil samples to identify contaminants and their concentrations.

-

Assess the ecological impact on local ecosystems.

-

Determine the potential pathways for soil contaminants to reach groundwater.

-

3. Water Pollution and Marine Impact Assessment;

Collect water samples from nearby water bodies affected by the factory's operations.

-

Analyze water samples for chemical contaminants and assess water quality.

-

Evaluate the discharge practices of the factory into the water bodies.

Aims:

-

Sediment and Marine Impact Assessment:

-

Conduct sediment sampling to evaluate the deposition of contaminants in water bodies.

-

Assess the impact on marine life and aquatic ecosystems.

-

Evaluate potential risks to local fisheries and ecosystems.

-

Data Integration and Synthesis:

-

Combine and synthesize the data collected from air, ground, soil, water, and marine assessments.

-

Identify potential linkages and interactions between the different environmental compartments.

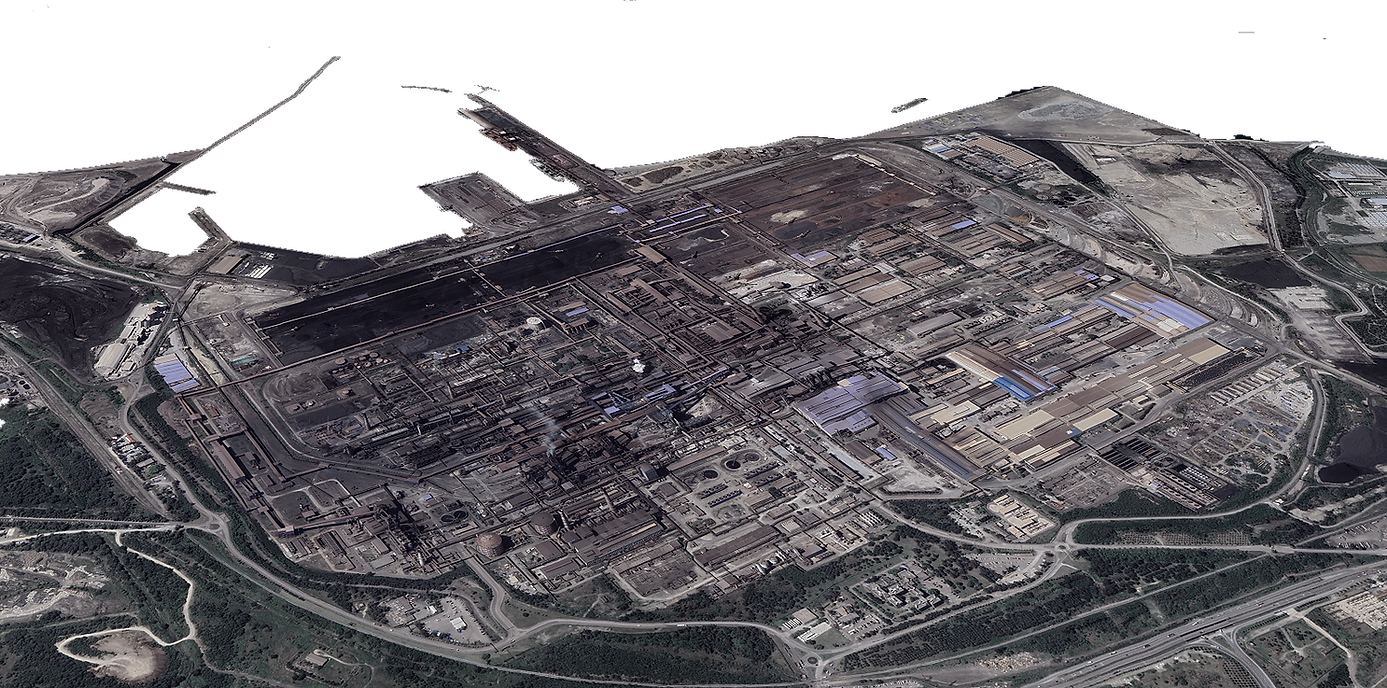

İSDEMIR, Hatay

"Integrated Iron and Steel facilities have developed recovery methods for slag, flue dust and scale that come from different points during the final production process. There is a need to initiate studies on iron-containing sledges coming from Blast Furnaces and Steel Mills, which pose a significant problem for the Turkish iron and steel industry, and to develop those that have already started. The EU's strict environmental laws seem to put the iron and steel industry in trouble in this field in the near future.

Throughout İSDEMİR, due to the use of galvanized scrap in the steel mill converters, the amount of zinc in the muddy waters coming from the steel mill gas cleaning has increased excessively (average 1.55) and can sometimes reach values such as 3-4, causing an increase in the zinc entering the sinter blend. This high zinc sludge cannot be evaluated in the system; It both causes environmental pollution and causes the 50-55 Fe grade ore obtained by precipitating and drying the sludge to not be utilized. Currently, slime obtained by drying the sludge contains high Zn."

The high zinc content in steel mill and blast furnace sludge causes problems in the blast furnace process, despite its value due to its iron content. These sludges have good properties that are difficult to recycle and cannot be used directly in sintering furnaces or blast furnaces. Zinc compounds in quantity will not enter the liquid pig iron and slag, but will be reduced at the bottom of the furnace, forming zinc or zinc oxide in the air.

These particles in the air form a thick zinc oxide layer on the load. The upper wall of the furnace helps produce fayalite and magnesia in the furnace. These compounds are difficult to reduce and cause production losses. The evaporated FeO acts as a catalyst, causing the bricks to crack, and the brick problem is further exacerbated by the amount of zinc and alkalis.

The cost of collecting waste that cannot be recycled with zinc has increased over time. Landfill costs $7 to $10 per ton, $20 in limited areas, and $100-$150 for hazardous waste.

Due to the negative impact on the performance of the furnace, it is important to limit the amount of zinc entering the furnace to a value below 0.180 kg/tonne of molten metal. Approximately 70% of the amount of zinc entering the sinter furnace demonstrates the importance of controlling the zinc in the sinter.

WATER

Water pollution

Border condition

see ownership

Water outlet & inlet pipeline

water intlet, effluent outlet, oil inlets etc.

Cooling Processes:

Water Supply: Steel manufacturing facilities extensively utilize substantial volumes of water for cooling applications throughout diverse production stages, encompassing the cooling of hot steel and machinery.

Re-circulation Systems: To enhance water efficiency, many steel mills integrate re-circulation systems aimed at optimizing water consumption through the re-utilization of cooling water.

Processing of Raw Materials:

Cleaning and Conditioning: Water plays a vital role in the cleaning and conditioning of raw materials as part of the preparatory steps for the steel-making process.

AIR

Air pollution

Air quality

People and borders condition

Air Pollution and Its Impact on the Population of İsdemir:

The residents of İskenderun unequivocally identify "air pollution" as a predominant environmental concern, marking it as a prevailing perception within the community. Survey participants express a pervasive acknowledgment of continual encounters with air pollution in their daily lives, resulting in deleterious health outcomes. Within this context, the social environment emerges as the primary conduit for information dissemination concerning environmental issues for the populace of İskenderun.

Participants in the survey exhibit a discerning awareness of the principal sources of air pollution within their region. A noteworthy consensus delineates industrial facilities as the primary contributors to the prevailing air pollution in İskenderun. Enumerated among the key sources of air pollution, as delineated by the local population, are industrial operations, vehicular emissions, the utilization of wood and coal for residential heating, and the incineration of waste materials.

Water Pollution:

Chemical Discharges: The discharge of water containing chemicals employed in diverse industrial processes can result in water pollution, exerting adverse effects on aquatic ecosystems.

Heavy Metals: The presence of heavy metals in discharged water, such as chromium or lead, can impart deleterious consequences on aquatic life, further exacerbating water quality concerns.

Thermal Pollution:

Temperature Changes: The release of heated water utilized in cooling processes can induce alterations in the temperature of receiving water bodies, thereby potentially impacting aquatic organisms and disrupting established ecosystems.

Sedimentation:

Runoff Contamination: The runoff emanating from steel mills possesses the capacity to transport sediments into adjacent water sources, consequently influencing water quality and impeding visual clarity.

Ecosystem Disruption:

Alteration of Habitat: Modifications in water flow patterns arising from intake and discharge operations can disrupt the delicate balance of aquatic habitats, potentially leading to ecological disturbances.

water table published by isdemir factory on 2022 annual reports

While some of these sections do not currently exist in reality, they have been included in the schematic map due to being relevant to the planning study.

The discernible impact of air pollution on İskenderun's residents is most acutely felt during the transitional period from summer to winter. The proclivity for employing wood or coal, particularly the latter due to its economic viability, for household heating constitutes a prevalent practice among the populace.

Despite the elevated public awareness of air pollution in İskenderun, the survey data posits that the requisite attitudes and behaviors for effective mitigation remain in an incipient stage of development. The inclination to recognize the problem and communicate concerns to relevant authorities appears circumscribed, indicating a need for further empirical investigation aimed at fostering environmentally conscientious habits within the community.

SOIL

Soil pollution

Soil quality

Greenery condition

"Correlation matrix for measured parameters (Statistically significant (p<0.05) 'r' values are written in bold)."

Reference: Odabaşı, M., Bayram, A., Elbir, T., Seyfioğlu, R., Dumanoglu, Y., & ÖrnekTekin, S. (2008). HATAY-İSKENDERUN BÖLGESİNDEKİ DEMİR-ÇELİK ENDÜSTRİLERİNDEN YAYINLANAN HAVA KİRLETİCİ EMİSYONLARININ TOPRAK KİRLİLİĞİNE ETKİSİ. In Hava Kirliliği ve Kontrolü Ulusal Sempozyumu‐2008 (pp. 581). Hatay, Turkey.

The local variation of PAH (Polycyclic Aromatic Hydrocarbons), PCB (Polychlorinated Biphenyls), PCN (Polychlorinated Naphthalenes), and PBDE (Polybrominated Diphenyl Ethers) concentrations in the soil.

"IT HAS GIVEN US HOPE"

ERDEMİR GROUP CARRIES OUT ITS OPERATIONS AS A CORPORATE

CITIZEN WHICH RESPECTS SOCIETY, PEOPLE, AND THE

ENVIRONMENT. IT CONTINUES ITS WORK WITH THE OBJECTIVE OF

LEAVING A SUSTAINABLE WORLD FOR FUTURE GENERATIONS."

(Isdemir annual report, 2014)

heavy metals (HMs) such as Fe, Zn, Mn, Cu, Hg, Ni, Cd, Co, and arsenic are accumulated in soils through imbalanced use of pesticides, chemical fertilizers, and also from waste industrial and disposal sewage water (Aydinalp and Marinova 2009). These HMs contaminate groundwater through leaching and also store in soil surface (Gupta and Ali 2012;Daghan and Ozturk 2015;

Metals like Fe, Mn, Cu, Ni, Co, Cd, Zn, Hg, and As have been accumulating in soils for a long time as a result of anthropogenic activities like the waste of different industries, application of fertilizer, sewage disposal and smelting (Zhang and Wang, 2020). Metals are leached into groundwater or accumulated on the soil surface because of these activities (Dağhan and Ozturk, 2015;Hakeem et al., 2015;Basheer, 2018)

DİVHAN A.Ş.,

located in the Divriği district of Sivas, was acquired through a tender by Ereğli Iron and Steel Factories Inc. on April 15, 2004, and its company name was changed to Erdemir Mining Industry and Trade Inc. The company owns 9 iron ore fields and 1 manganese field.

Cürek Yolu 5. Km Divriği / Sivas

"The points where high POP concentrations are measured in the soil include settlements such as Payas and ISDEMIR residences. Considering previous studies, it is believed that the outdoor air concentrations in these areas are also high, and a significant number of people are exposed to these pollutants."

Reference: Hava Kirliliği ve Kontrolü Ulusal Sempozyumu‐2008, 22‐25 Ekim 2008, HATAY

Public Health Concerns: (People and borders)

Contamination of Drinking Water: Should pollutants from the industrial facility infiltrate local water supplies, there exists the potential for heightened health risks within communities reliant on these sources for potable water.

Air Pollutants: Airborne pollutants associated with water utilization and treatment processes can yield health implications for nearby residents, emphasizing the interconnectedness of air and water quality.

Regulatory Compliance:

Environmental Regulations: Steel manufacturing plants are obligated to adhere to stringent environmental regulations and standards, aimed at effectively managing and mitigating the multifaceted impact of water usage on both the environment and public health.

Collective endeavors to tackle these challenges typically encompass the implementation of advanced water recycling and treatment systems, the adoption of cleaner production technologies, and steadfast adherence to established environmental standards. These measures collectively contribute to the reduction of the environmental footprint associated with water usage in the steelmaking industry.

Dust Suppression:

Control of Airborne Dust: Water is employed for the suppression of dust, serving to regulate airborne particulate matter generated during various manufacturing procedures.

Chemical Reactions:

Chemical Processes: Water serves as a pivotal element in several chemical reactions integral to steel-making, including the elimination of impurities and the formation of desired alloys.

The local variation of SO₄²⁻, Cl⁻, Zn, and Pb concentrations in the soil.